Wires from a voltmeter. Connecting voltmeters to the network

D.C does not change direction in time. An example would be a battery in a flashlight or radio, or a battery in a car. We always know where the positive mark of the power supply is and where the negative mark is.

Alternating current- this is a current that changes the direction of movement with a certain periodicity. This current flows in our socket when we connect a load to it. There is no positive and negative pole, but only phase and zero. The voltage at zero is close in potential to the ground potential. The potential at the phase output changes from positive to negative with a frequency of 50 Hz, so the current under load will change its direction 50 times per second.

During one period of oscillation, the current increases from zero to maximum, then decreases and passes through zero, and then the reverse process occurs, but with a different sign.

Receiving and transmitting alternating current is much easier than direct current: there is less energy loss. With the help of transformers, we can easily change the alternating current voltage.

When transmitting high voltage, less current is required for the same power. This allows for more subtle arguments to be used. Welding transformers use the reverse process - they lower the voltage to increase the welding current.

In an electrical circuit, it is necessary to connect an ammeter or milliammeter in series with the electricity receiver. At the same time, in order to exclude the influence of the measuring device on the operation of the consumer, it must have a very small internal resistance, so that in practice it could be taken equal to zero, so that the voltage drop across the device could simply be neglected.

The ammeter is always connected in series with the load. If you connect an ammeter in parallel with the load, in parallel with the power source, then the ammeter will simply burn out or the source will burn out, since all the current will flow through the meager resistance of the measuring device.

The measurement limits of ammeters intended for measurements in DC circuits are expanded by connecting the ammeter not directly with the measuring coil in series with the load, but by connecting the ammeter measuring coil in parallel with the shunt.

Thus, only a small part of the measured current will always pass through the coil of the device, the main part of which will flow through the shunt connected in series to the circuit. That is, the device will actually measure the voltage drop across a shunt of known resistance, and the current will be directly proportional to this voltage.

In practice, the ammeter will work as a millivoltmeter. However, since the instrument scale is graduated in amperes, the user will receive information about the magnitude of the measured current. The shunt factor is usually chosen as a multiple of 10.

Shunts designed for currents up to 50 amperes are mounted directly into device housings, and shunts for measuring high currents are made remote, and then the device is connected to the shunt with probes. For devices designed for continuous operation with a shunt, the scales are immediately graduated in specific current values, taking into account the shunt coefficient, and the user no longer needs to calculate anything.

If the shunt is external, then in the case of a calibrated shunt, the rated current and rated voltage are indicated on it: 45 mV, 75 mV, 100 mV, 150 mV. For current measurements, choose a shunt such that the needle deviates maximum - the entire scale, that is, the rated voltages of the shunt and the measuring device must be the same.

If we are talking about an individual shunt for a specific device, then everything, of course, is simpler. According to accuracy classes, shunts are divided into: 0.02, 0.05, 0.1, 0.2 and 0.5 - this is the permissible error in fractions of a percent.

Shunts are made of metals with a low temperature coefficient of resistance and a significant resistivity: constantan, nickel, manganin, so that when the current flowing through the shunt heats it up, this would not affect the readings of the device. To also reduce the temperature factor during measurements, an additional resistor made of the same kind of material is connected in series with the ammeter coil.

To connect a voltmeter between two points in the circuit, parallel to the circuit, between these two points. The voltmeter is always connected in parallel to the receiver or source. And so that the connected voltmeter does not affect the operation of the circuit, does not cause a decrease in voltage, does not cause losses, it must have a sufficiently high internal resistance so that the current through the voltmeter can be neglected.

And in order to expand the measurement limits of the voltmeter, an additional resistor is connected in series with its working winding, so that only part of the measured voltage falls directly on the measuring winding of the device, in proportion to its resistance. And with a known value of the resistance of the additional resistor, the total measured voltage acting in a given circuit can be easily determined from the voltage recorded on it. This is how all classic voltmeters work.

The coefficient that appears as a result of adding an additional resistor will show how many times the measured voltage is greater than the voltage falling on the measuring coil of the device. That is, the measurement limits of the device depend on the value of the additional resistor.

An additional resistor is built into the device. To reduce the influence of ambient temperature on measurements, the additional resistor is made of a material with a low temperature coefficient of resistance. Since the resistance of the additional resistor is many times greater than the resistance of the device, the resistance of the measuring mechanism of the device ultimately does not depend on temperature. The accuracy classes of additional resistors are expressed similarly to the accuracy classes of shunts - in fractions of a percent they indicate the magnitude of the error.

To further expand the measurement limits of voltmeters, voltage dividers are used. This is done so that when measuring, the device receives a voltage corresponding to the device’s rating, that is, it does not exceed the limit on its scale. The voltage divider division ratio is the ratio of the input voltage of the divider to the output measured voltage. The division coefficient is taken equal to 10, 100, 500 or more, depending on the capabilities of the voltmeter used. The divider does not introduce a large error if the resistance of the voltmeter is also high and the internal resistance of the source is low.

AC current measurement

To accurately measure alternating current parameters with the device, an instrument transformer is required. An instrument transformer used for measurement purposes also provides safety for personnel, since the transformer ensures galvanic isolation from the high voltage circuit. In general, safety precautions prohibit connecting electrical measuring instruments without such transformers.

The use of instrument transformers makes it possible to expand the measurement limits of instruments, that is, it becomes possible to measure high voltages and currents using low-voltage and low-current instruments. Thus, instrument transformers are of two types: voltage transformers and current transformers.

Voltage transformer

To measure alternating voltage, a voltage transformer is used. This is a step-down transformer with two windings, the primary winding of which is connected to two points in the circuit between which the voltage needs to be measured, and the secondary winding is connected directly to the voltmeter. Instrument transformers are depicted in the diagrams as ordinary transformers.

A transformer without a loaded secondary winding operates in no-load mode, and when a voltmeter is connected, the resistance of which is high, the transformer remains practically in this mode, and therefore the measured voltage can be considered proportional to the voltage applied to the primary winding, taking into account the transformation ratio equal to the ratio of the number of turns in its secondary and primary windings.

This way you can measure high voltages while still providing a small, safe voltage to the device. All that remains is to multiply the measured voltage by the transformation ratio of the measuring voltage transformer.

Those voltmeters that were originally designed to work with voltage transformers have a scale calibration taking into account the transformation ratio, then the value of the changed voltage is immediately visible on the scale without additional calculations.

In order to increase safety when working with the device, in case of damage to the insulation of the instrument transformer, one of the terminals of the secondary winding of the transformer and its frame are first grounded.

Instrument current transformers

Measuring current transformers are used to connect ammeters to alternating current circuits. These are two-winding step-up transformers. The primary winding is connected in series to the circuit being measured, and the secondary winding is connected to the ammeter. The resistance in the ammeter circuit is small, and it turns out that the current transformer operates practically in short circuit mode, and we can assume that the currents in the primary and secondary windings are related to each other as the number of turns in the secondary and primary windings.

By selecting a suitable ratio of turns, significant currents can be measured, while fairly small currents will always flow through the device. All that remains is to multiply the current measured in the secondary winding by the transformation ratio. Those ammeters that are designed for continuous operation in conjunction with current transformers have scales calibrated taking into account the transformation ratio, and the value of the measured current can be easily read from the device scale without calculations. In order to increase personnel safety, one of the terminals of the secondary winding of the measuring current transformer and its frame are first grounded.

In many applications, pass-through measuring current transformers are convenient, in which the magnetic core and secondary winding are insulated and located inside a feed-through housing, through the window of which a copper bus carrying the measured current passes.

The secondary winding of such a transformer is never left open, because a strong increase in the magnetic flux in the magnetic circuit can not only lead to its destruction, but also induce an EMF on the secondary winding that is dangerous for personnel. To carry out a safe measurement, the secondary winding is shunted with a resistor of a known value, the voltage on which will be proportional to the current being measured.

Instrument transformers are characterized by two types of errors: angular and transformation ratio. The first is associated with the deviation of the phase angle of the primary and secondary windings from 180°, which leads to inaccurate readings of wattmeters. As for the error associated with the transformation ratio, this deviation shows the accuracy class: 0.2, 0.5, 1, etc. - as a percentage of the nominal value.

Andrey Povny

Do-it-yourselfers, designing, developing and implementing a variety of charger or power supply circuits, are constantly faced with an important factor - visual monitoring of the output voltage and current consumption. Here Aliexpress very often lends a helping hand, promptly supplying Chinese digital measuring instruments. In particular: a digital ampere-voltmeter is a very simple device, affordable and displays quite accurate information data.

But for beginners, commissioning (connecting an ampere-voltmeter to the circuit) can be a problematic task, since the measuring device comes without documentation and not everyone can quickly connect the color-coded wires.

An image of one of the most popular voltammeters among homemade people is posted below,

This is a 100 volt/10 amp ampere-voltmeter and comes with a built-in shunt. Many radio amateurs quite often purchase such measuring instruments for their homemade products. A digital device can be powered either from separate sources,

and from one operated and measured voltage source. But there is a small nuance hidden here; the condition must be met - the voltage of the power source used was within 4.5-30 V.

For DIYers who still don’t quite understand: connect the thick black wire to the minus of the power supply, the thick red wire to the plus of the power supply (the voltmeter scale readings will light up),

We connect a thick blue wire to the load, the second end from the load goes to the plus of the power supply (the ammeter scale readings will light up).

To successfully monitor the state of charge of the battery, it is important to know how to connect a voltmeter in the car and how to decipher its readings. Since the advent of cars equipped with an on-board computer, the need for a separate voltmeter has faded into the background, because it does not provide complete monitoring of all electrical components of the car. The relevance of the device is also determined by the need to constantly monitor the battery charge, which is especially important in winter. In the event of a sharp drop in voltmeter readings, it becomes possible to take appropriate countermeasures and avoid unexpected engine shutdown.

Voltmeter is a useful device for cars that do not have an on-board computer. Using it you can monitor the battery charge status.

The principle of operation of a voltmeter in a car

A voltmeter is a device with a fairly simple internal structure, the main purpose of which is to measure the voltage in the network. The principle of operation of a voltmeter is the interaction between an electromagnetic coil and a permanent magnet or two electromagnets. The current passing through the coil deflects the voltmeter needle the more strongly, the higher the voltage value.

In modern devices, readings are converted into a digital display, which is clearly visible even at night in an unlit car interior. The accuracy of such sensors is much higher than analogue “pointer” models, and depends on the discreteness of the main component - the analog-to-digital converter. The input voltage, flowing through the wires, is converted into a digital signal, which is then converted from binary code to a numerical value and displayed on a backlit display.

Selecting a voltmeter model

Digital voltmeter circuit.

The modern market of devices for cars offers a wide selection of voltmeter models. The most popular types of devices are:

- analog “pointer” voltmeters - installed mainly on domestic cars, connecting to the dashboard instead of a clock,

- digital sensors connected to the cigarette lighter socket,

- digital voltmeters mounted in the dashboard.

The last two types of devices are most often used, as they combine a modern appearance, accurate readings and ease of installation.

The measurement results that best correspond to reality are provided by voltmeters connected directly to the dashboard. Although their installation is sometimes fraught with some difficulties, by installing them you can get constant monitoring of the battery condition, which is especially important when there are a large number of connected components. Automotive voltmeter

The cost of a digital voltmeter is quite low and ranges from 120-150 rubles if ordered through online stores. It has a standard rectangular shape, thanks to which it will harmoniously fit into the interior of any car. Backlight color – white, yellow, blue, green, red. Sometimes a problem arises with the high brightness of the screen, which acts as a distraction and makes it difficult to concentrate on the road, but this problem can be quickly solved with the help of a tint film.

Installation specifics

Table of characteristics of a digital voltmeter.

If there are no problems during installation with digital voltmeters that are powered from the cigarette lighter, then models installed directly into the dashboard often force drivers to think about the order in which they are connected.

Most voltmeters on the market have two or three wires for connecting to the network, although there are models with four contacts. The wires have standard color markings:

- the red wire corresponds to “plus”,

- the black wire is connected to the negative

- The white wire is responsible for controlling the backlight intensity and turning the device on and off.

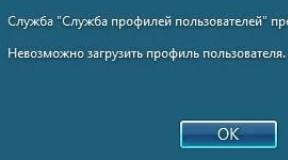

In some cases, an unexpected problem arises when connecting the voltmeter in this way: it lights up dimly or refuses to work at all. The reason may be the alternative marking of the wires, in which the white wire is responsible for the “minus”, and the black wire for controlling the device.

The voltage sensor is installed in the standard place of the clock, but in some cases, when it is impossible to find free space for the voltmeter, you have to make a hole for it directly in the dashboard.

An excellent place to connect the device is the dashboard plug on the left side of the steering wheel. It is small in size and easy to remove and secure for processing.

Figure 1. Connection diagram for a voltmeter with a pulse stabilizer.

The voltmeter body has a raised surface: the frame around the display will protrude above the surface of the car panel. Thanks to this, the device will not fall inside the mounting socket, and will also hide uneven edges of the hole.

Inexpensive models of voltmeters may not have a separate wire for power; such a device is connected via three contacts on the sensor body (Fig. 1). In this case, the voltmeter is connected using a 4-wire wire from the computer drive (Fig. 2). The wide IDE format connector is cut off, and the remaining wiring is attached by soldering to the contacts of the car wiring. The 4-pin contact ensures a good connection and makes it possible, if necessary, to quickly and effortlessly replace the voltmeter if it breaks down.

Regardless of the structural features of the voltmeter, before installing it, the car’s wiring diagram is studied in detail, according to which the location of the device’s connection is determined. It would also be a good idea to carefully read the instructions for the device, since the methods for connecting it may differ.

Interpretation of instrument readings

Installing a voltmeter is only the first step in gaining control over the condition of the vehicle's battery and electrical system. Complete information can be obtained only by determining the basic values of the device indicators.

The standard battery voltage in passenger cars is 12 V. The on-board voltage readings will be slightly different, amounting to 13.7-14 V. If the values on the voltmeter decrease relative to the specified parameters, this may indicate a breakdown of the voltage regulator or a malfunction in the generator.

A decrease in voltage may also be due to the battery being discharged. This happens especially often in winter: in the cold, discharge occurs faster, and the presence of a heater in the car adds load to the network.

Figure 2. Diagram of connecting a voltmeter to a circuit.

If the voltmeter is connected directly to the battery terminals, then by its numerical values you can easily find out the battery charge level. Readings in the range of 12.6-12.9 V indicate that your battery is fully charged. As the discharge progresses, the voltage gradually drops. At a value of 12.3-12.6 V, the charge drops to 75%; at 12.1-12.3 V, the battery is approximately half discharged. With a gradual decrease in voltage to 11.8-12.1 V, the battery is considered 3/4 empty, and at 11.5-11.8 V you will no longer be able to start the car.

To obtain complete information about the state of the network, it would be a good idea to measure the voltage directly at the battery terminals, and then compare it with the readings of the on-board voltmeter. If, when you turn on the heating, high beams or other loads, the voltage differs by more than 0.4 V, this may indicate an unstabilized on-board network. In this case, it is necessary to check the serviceability of the generator and voltage relay as soon as possible.

Conclusion on the topic

The question of how to properly connect a voltmeter in a car should be approached with all responsibility.

This simple device will allow you to keep close attention to the condition of the battery, thereby providing an additional tool for monitoring the electrical system of your car.

The variety of modern models of voltmeters, their accessibility for any driver and ease of installation make it possible to equip any model of car with this device.

car voltmeter

Assembling a loud audio system in a car. Part 1. Nutrition.

Description:

I tell you in detail how loud music will be assembled in the car. In this part I will talk about preparing the car immediately before installing the music. In this part we deal with voltmeters, car wiring, and everything related to reliable electrics.

Tracks:

Ceanty-easy

Erio-Monolith

Foreword & Matters - Journey

MDC-Home

Vassh-wet walls

How to install a Voltmeter in a car

Description:

I'll tell you how to install a portable voltmeter in a car.

Situations when a voltmeter should be at hand occur quite often. To do this, there is no need to use a complex factory device. Making a simple voltmeter with your own hands is not a problem, because it consists of two elements: a pointer measuring unit and a resistor. True, it should be noted that the suitability of a voltmeter is determined by its input resistance, which consists of the resistances of its elements.

But it is necessary to take into account the fact that there are different resistors with different values, and this means that the input resistance will depend on the installed resistor. That is, by choosing the right resistor, you can make a voltmeter to measure certain network voltage levels. The measuring device itself is more often evaluated by the indicator - relative input resistance per one volt of voltage, its unit of measurement is kOhm / V.

That is, it turns out that the input resistance in different measured areas is different, but the relative value is a constant indicator. In addition, the less the arrow of the measuring block deviates, the greater the relative value, and, therefore, the more accurate the measurements will be.

Multi-limit instrument

Anyone who has repeatedly encountered transistor designs and circuits knows that very often with a voltmeter it is necessary to measure circuits with voltages from tens of fractions of one volt to hundreds of volts. A simple homemade device with one resistor will not do this, so you will have to connect several elements with different resistances to the circuit. So that you understand what we are talking about, we suggest that you familiarize yourself with the diagram located below:

It shows that there are four resistors installed in the circuit, each of which is responsible for its own measurement range:

- From 0 volts to one.

- From 0 volts to 10V.

- From 0 V to 100 volts.

- From 0 to 1000 V.

The value of each resistor can be calculated based on Ohm's law. The following formula is used here:

R=(Uп/Iи)-Rп, where

- Rп is the resistance of the measuring unit, take, for example. 500 Ohm;

- Up is the maximum voltage of the measured limit;

- Ii is the current strength at which the needle deflects to the end of the scale, in our case - 0.0005 amperes.

For a simple voltmeter from a Chinese ammeter, you can choose the following resistors:

- for the first limit – 1.5 kOhm;

- for the second – 19.5 kOhm;

- for the third – 199.5;

- for the fourth – 1999.5.

But the relative resistance value of this device will be equal to 2 kOhm/V. Of course, the calculated values do not coincide with the standard ones, so resistors will have to be selected close in value. Next, the final adjustment is carried out, during which the device itself is calibrated.

How to convert a DC voltmeter into AC voltage

The circuit shown in Figure 1 is a DC voltmeter. To make it variable or, as experts say, pulsating, it is necessary to install a rectifier in the design, with the help of which the direct voltage is converted into alternating voltage. In Figure 2, an AC voltmeter is shown schematically.

This scheme works like this:

- when there is a positive half-wave at the left terminal, diode D1 opens, D2 in this case is closed;

- voltage passes through the ammeter to the right terminal;

- when the positive half-wave is at the right end, then D1 closes and no voltage passes through the ammeter.

A resistor Rd must be added to the circuit, the resistance of which is calculated in exactly the same way as the other elements. True, its calculated value is divided by a coefficient equal to 2.5-3. This is the case if a half-wave rectifier is installed in the voltmeter. If a full-wave rectifier is used, then the resistance value is divided by a coefficient: 1.25-1.5. By the way, the diagram of the latter is shown in Figure No. 3.

How to properly connect a voltmeter

Anyone who does not know, but wants to check the voltage on some part of the electrical network, must ask the question - how to connect a voltmeter? This is actually a serious question, the answer to which lies in a simple requirement - the voltmeter must be connected only in parallel with the load. If a serial connection is made, the device itself will simply fail and you may receive an electric shock.

The thing is that with such a connection the current strength acting on the measuring device itself decreases. At this resistance, it does not change, that is, it remains large. By the way, never confuse a voltmeter with an ammeter. The latter is connected to the circuit in series to reduce the resistance to a minimum.

And the last question on the topic is how to use a voltmeter that you made yourself. So, your device has two probes. One is connected to the neutral circuit, the second to the phase. You can also check the voltage through the socket, having previously determined which socket is powered by zero and which by phase. Or connect the device in parallel to the area being measured. The arrow of the measuring block will show the voltage value in the network. This is how they use this homemade measuring device.

How to connect a voltmeter?

In any modern car with an on-board computer, you can find out the voltage of the on-board network. But what should car enthusiasts who do not have a car with an on-board computer do? To do this, you can install the voltmeter yourself, it’s not difficult.

The question arises, why even know the voltage of the on-board network? The fact is that the machine is a large consumer of electricity during its operation. And in order for energy not only to be spent, but also to accumulate in the battery, you need to have a voltage in the on-board network higher than at the battery terminals. How to connect a voltmeter?

Connecting a voltmeter

The voltmeter is connected to the network in parallel. Since the entire car body is “minus”, the negative terminal can be connected to any point of “ground”. And it makes sense to connect the positive wire to the “plus” of the generator so that you can know the voltage produced by the generator. This is usually 14 volts.

Wires for connection should be chosen with a thicker cross-section so that there are no errors in determining the voltage. It is also necessary to install a fuse in the circuit if it is not provided in the voltmeter itself.